Vacuum Sewerage Systems

Corodex Electromechanic is the regional leader in providing the best of engineering services. In partnership with the Roediger Vacuum (under Aqseptence Group), Corodex Electromechanic provides world-class MEP services of vacuum sewerage and water transmission systems.

Technology

VACUUM SEWERAGE SYSTEMS

Vacuum sewerage systems are wastewater collection systems.

An air stream generated by differential air pressure drives the wastewater toward a vacuum station.

Vacuum sewer systems are…

• Collection Systems for domestic waste water.

• Easy to install systems for waste water within low and medium dense residential, industrial, commercial or mixed use areas

• State of technology, eco-friendly, safe and operator friendly systems (DWA-A 116-1, EN1091, WEF, EPA)

• Alternatives for conventional gravity sewer systems under difficult conditions

Vacuum sewer systems are NOT…

• Transportation system for waste water (pumping station replacement).

• Main collectors for large sewer systems.

APPLICATIONS…

• Flat terrain und lack of natural slope

• Little flows and long distances within expanded municipalities with seasonal flows within resorts

• High ground water tables

• Unstable underground (Rocky, sandy or swampy)

• Ecologically sensitive areas

• Existing infrastructure, limited construction space

Example of Applications…

• Low dense residential, industrial, commercial or mixed used developments

• Holiday resorts with villas and bungalows and/or seasonal flows

• Marinas, corniche promenades and harbours

• Rehabilitation of existing sewer systems

• Installation of sewer systems within existing developments.

• Natural or artificial Islands, reclaimed land

• Flood areas or areas exposed to sea and river tides

COMPONENTS OF VACUUM SEWERAGE SYSTEM

A vacuum sewer system consists of:

Vacuum Station

Where the vacuum is generated, the wastewater is collected, then pumped to a wastewater treatment facility.

Vacuum Pipeline System

Typically consisting of a branched network of vacuum sewer pipe.

Collection Chambers

Collection chambers with sumps and interface valve units.

Palm Jumeirah Project

Location: Palm Jumeirah – Dubai, UAE.

Scope Of Work: Design, engineering installation and commissioning of vacuum sewerage

network for the Palm Jumeirah Island.

Description: The vacuum sewerage system supplied by

Roediger Vacuum Gmbh, supported more than 2,000 villas,

having 900 collection chambers and 40 km of vacuum sewer

line connected to a central Roevac vacuum station, which is

installed underground in the utilities building on Palm Jumeirah.

The vacuum station for the Palm Jumeirah Development, with a

capacity to connect 23,000 persons, is the largest single

vacuum station in the world. The design of the vacuum sewerage

system conforms to European Standards EN 1091 and the design guidelines

of the German Wastewater Association.

Client: Nakheel.

Al Raha Garden

Location: Al Raha Garden – Abu Dhabi, UAE

Scope Of Work: Scope of work includes designing, engineering, installation and commissioning of vacuum sewerage system for Al Raha Garden.

Description: TThe system supports 750 villas (4,000 PE) and has 171 vacuum valves and 6 km vacuum lines to 1 vacuum station in this distinguished community development. A traditional gravity system of the same size would have required 1 & ½ years, while vacuum sewerage system was completed in 5 months.

Client: Al Dar.

Durrat Al Bahrain Resort

Location: Manama- Bahrain.

Scope Of Work: Roediger supplied the vacuum sewerage system components for Durrat Al Bahrain Resort in Bahrain.

Description: The vacuum system supports 1,600 villas of an approximate population of 10,500 within 11 islands. It has 440 vacuum chambers with 3 inch-valves and 28 km vacuum lines to 3 vacuum stations.

Client: Durrat Khaleek Al Bahrain Co. DSC.

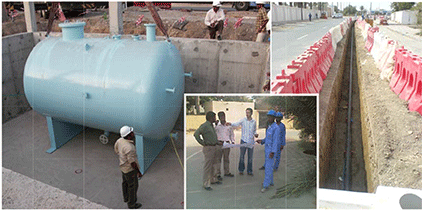

Umm Al Quwain Marina

Location: Umm Al Quwain , UAE.

Description: Approx. 5 km vacuum pipe network

277 Villas

Approx. 50 vacuum collection chambers

Finished in less than 6 months complete design-build

1 Vacuum Station

20m³ vessel

3 x 11 KW vacuum pumps

2 x 4.7 KW discharge pumps

Client: Emaar Properties.

Qatalum Aluminium Plant

Location:Qatar

Description:

SNC Lavalin, Canada

5.5 km pipe network

63 vacuum collection chambers

1 Vacuum Station

20m³ vessel

6 x 5.5 KW vacuum pumps

2 x 13.5 KW discharge pumps

Client: Qatalum (JV Qatar Petroleum + Hydro).

Lusail City, Phase 1, Qatar

Location: Qatar

Description:

Commercial buildings, restaurants, community retail, dining outlets, promenade facilities, mosque etc.

1 centrally located, underground Vacuum Station

46 fully flood proof and heavy duty Vacuum Z-type Collection Chambers

approx. 1.7 km of vacuum main lines

Odor Control Unit – activated carbon filter

Client: Qatari Diar.

Occidental Camp Mukhaizna, Oman

Location: Oman

Description:

Camp for 5.000 staff

app. 7 km vacuum lines

127 vacuum collection chambers

1 Vacuum Station

One of the hottest and most unfriendly climate conditions world wide

Oman A’Seeb Wastewater Project, Sultanate of Oman

Location: Sultanate of Oman

Description:

Approx. 100.000 PE

5 Vacuum stations

2.000 vacuum collection chambers

3,5 years construction time

Very narrow streets and old town areas

Replacement of existing septic tanks

Connecting new developments